We chose a technological innovation policy, not only strong management, looking to grow up near the market progress.

The synergy between our team and the technological investments enable us to offer answers and solutions to many different needs with quality products at interesting prices.

FILMAC production has two adhesive methods:

DISPERSION ACRYLIC

POLYMERS EMULSIFIED OR DISPERSED IN WATER, WITH THE POSSIBLE ADDITION OF ADDITIVES.

SYNTHETIC RUBBER:

MELTING AND HOT MIXING OF GUMS AND RESINS, HYDROCARBON AND NATURAL, WITH THE POSSIBLE ADDITION OF ADDITIVES.

Quality

The FILMAC production chain is almost completely verticalized with cutting-edge machinery and equipment. We operate in full compliance with safety laws and according to quality systems aligned with ISO standards.

With traditional skills and constant evolution, we have developed a production process with guaranteed quality because we continuously monitor processing requirements and systematically inspect the product.

We embrace this quality through attentive and dynamic service: this is why our daily challenge is also to focus on flexibility and speed.

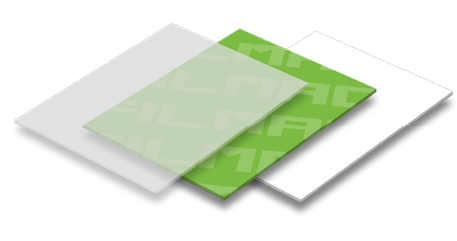

Sandwich print

Innovation means pay attention to research and development, making constant investments in one’s firm in order to achieve technologically advanced products. In response to a continuous marker demand for a qualitative standard, FILMAC proposes the ‘Sanwich print’, a process which allows us to insert the ink between film and adhesive; this make particularly clear, bright and indelible prints obtained.